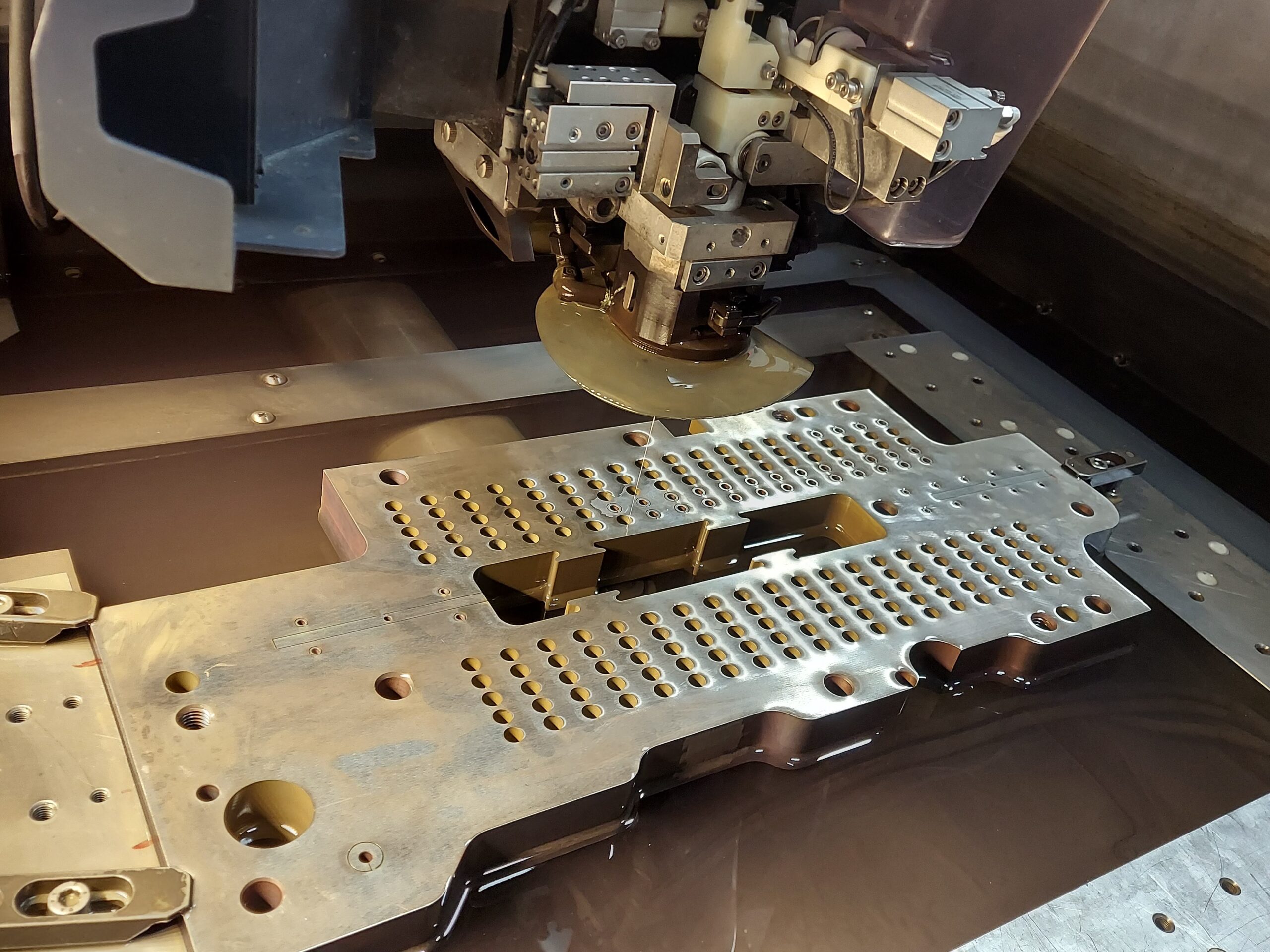

Our internal EDM staff have experience cutting various tool steels and aluminum with 3 Mitsubishi wire EDM machines that have a maximum range of 23 1/2” of travel. With our wire EDM capabilities, we can reduce costs and lead time in our “start to satisfaction” manufacturing process. With short lead times and competitive pricing, the RTD team is ready to manufacture high quality metal stamping dies!

Wire EDM is commonly used when low residual stresses are desired because it has no cutting forces, therefore there is little change in the mechanical properties of the material.

Applications for wire EDM include: the creation of die sections, blanking punches and other metal stamping tool components. With up-to-date BobCad software it gives the cutting edge ability to meet our close tolerance needs.